Six Tips to Optimize Your Plastic Material Conveying Equipment

2024-12-23 Page view:

Autoloader plays an essential role in plastic manufacturing production lines. It is used for raw and recycled material conveying for injection molding, blow molding, and extrusion. Loaders offer stable material conveying solutions, improves production efficiency, reduces labor costs, and ensures safety.

Autoloaders or vacuum loaders can be optimized to enhance the conveying capabilities. The goal is to support plastic manufacturers in enhancing the overall performance of their material conveying equipment. Here are six tips and recommendations to help you operating your loaders smoothly.

Flow Adjustment and Control:

To ensure that materials are supplied on demand, an intelligent control system can be set up to adjust the conveying volume and the speed of the conveying equipment in real time to adapt to changes in the demand of the production line and to avoid material backlogs or shortages.

Regular Maintenance and Monitoring:

Inspect and maintain key components of the conveying equipment regularly, including carbon brush motors, filter assemblies, automatic spray cleaning and dust removal devices, and stainless-steel hoppers.

Automatic Cleaning Function:

Wensui autoloader is engineered with an independent filtering device to remove excess dust, reduce manual workload, and improve the hygienic standard of the production environment.

Precise Control of Feeding and Discharging Quantity:

Through precise flow meter and control system, it ensures the precision of material loading and discharge. The control system reduces material wastage by preventing conveying excessive amount of material.

Prevent Material Accumulation:

During the conveying process, especially when conveying granules or powder material, avoid material accumulation or jamming inside the equipment. This can be prevented by adding cleaning and unloading functions.

Production Line Layout Planning:

A well-planned layout of the production facility is important. An efficient arrangement also reduces equipment interference, boosting overall production efficiency.

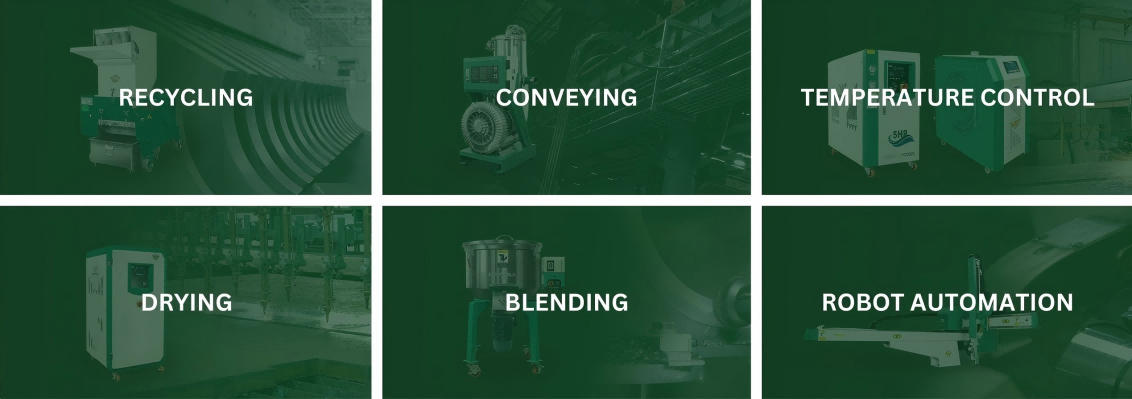

Conveying Equipment for Plastic Material

Our conveying equipment is designed to maximize loading and feeding capabilities. Our vacuum loaders offer low to high conveying throughputs and distances. Share your production requirements and material with us, we will deliver the right conveying equipment to you. We are a one-stop shop of auxiliary equipment for plastic processing applications. Get a free quote today.