Why Barrel-Shaped Plastics Are So Hard to Break and How to Recycle Them Efficiently

2024-12-26 Page view:

Barrel-shaped plastics are an essential part of our daily lives. From oil drums to water containers, these durable products are trusted for their strength and reliability. However, their robust design poses challenges during recycling. In this blog, we'll explore why barrel-shaped plastics are so tough, the reasons behind their durability, and how innovative crushers are addressing recycling challenges.

What Makes Barrel-Shaped Plastics So Durable?

Barrel-shaped plastics are designed to handle harsh conditions. They are commonly made from high-density polyethylene (HDPE) or polypropylene (PP), materials known for their exceptional toughness and impact resistance.

Their shape plays a key role in their durability. The curved structure evenly disperses pressure, preventing stress from concentrating in one spot. Combined with thicker walls, this design ensures they can withstand drops, hits, and heavy loads without breaking.

The Recycling Challenge of Barrel-Shaped Plastics

While their durability is an asset in everyday use, it becomes a problem during recycling. Crushing barrel-shaped plastics is not easy due to their resistance to deformation. Recycling facilities often face difficulties breaking them down efficiently, delaying the recycling process.

This issue highlights the need for specialized equipment to handle these materials. Without the right tools, the recycling of barrel-shaped plastics becomes labor-intensive and less efficient.

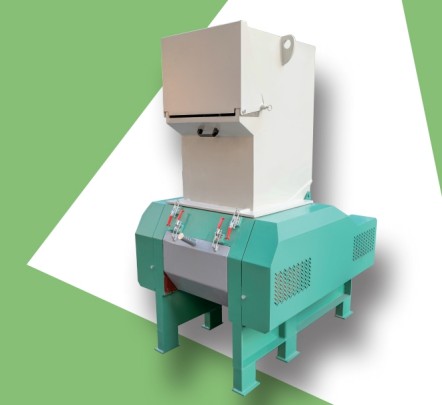

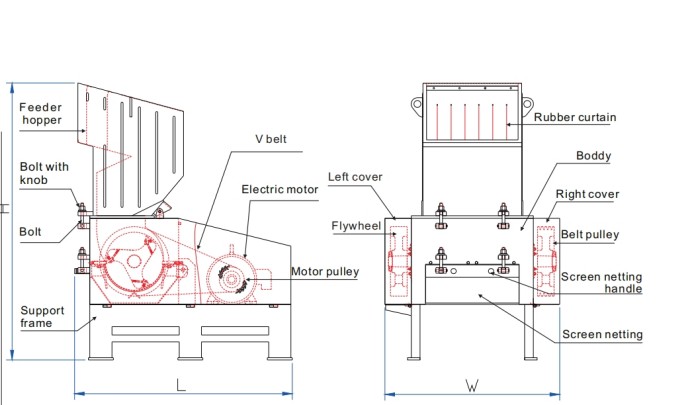

Introducing Wensui Group's WSGT Barrel Crusher

To tackle these challenges, Wensui Group developed the WSGT barrel crusher, a machine designed specifically for barrel-shaped plastics. This crusher is part of the GT series, known for processing hollow plastic products like bottles and barrels.

Key features of the WSGT crusher include:

Direct crushing: No manual cutting is required, ensuring faster processing.

Low power, high efficiency: Energy-efficient design saves costs while maximizing output.

Advanced blades: Adjustable front blades with a larger cutting angle for uniform results.

Durable construction: Stainless steel hopper with sound insulation and long-lasting sealed bearings.

How WSGT Crushers Benefit the Recycling Industry

The WSGT barrel crusher transforms the recycling process for barrel-shaped plastics. It reduces the time and effort needed for crushing, making recycling more efficient. By enabling the reuse of robust plastics, it also minimizes environmental impact.

This eco-friendly design not only solves recycling challenges but also supports the global push toward sustainable waste management. Facilities equipped with the WSGT crusher can handle larger volumes of waste plastics, reducing landfill contributions and conserving resources.

Barrel-shaped plastics are a staple in many industries due to their strength and durability. However, their robust design also makes them a challenge to recycle. With innovative solutions like Wensui Group's WSGT barrel crusher, the recycling industry is better equipped to process these tough materials.

By improving recycling efficiency and reducing environmental impact, machines like the WSGT play a vital role in sustainable development. As technology advances, we can look forward to even greener and more efficient recycling solutions for a better future.

-

2025-01